Efficient Data Management - from the Sensor to the Cloud

The increasing interconnectedness raises the requirements to IIoT-connected machines and installations. As the data world in the mostly organically grown structures is becoming more complex, the use of edge computing technology has become indispensable.

The edge separates the productive level OT (operational technology) of the installation or machine from the IT-level of the company. Edge Computing allows the targeted pre-processing and analysis of the data generated by sensors in real time.

Only relevant and therefore reduced data packages are transferred to the cloud, stationary servers are disburdened, and both the costs for data transmission and the risk of data loss outside the installation are reduced. The process-oriented analysis and processing of the data also simplifies their further use for predictive maintenance and quality assurance.

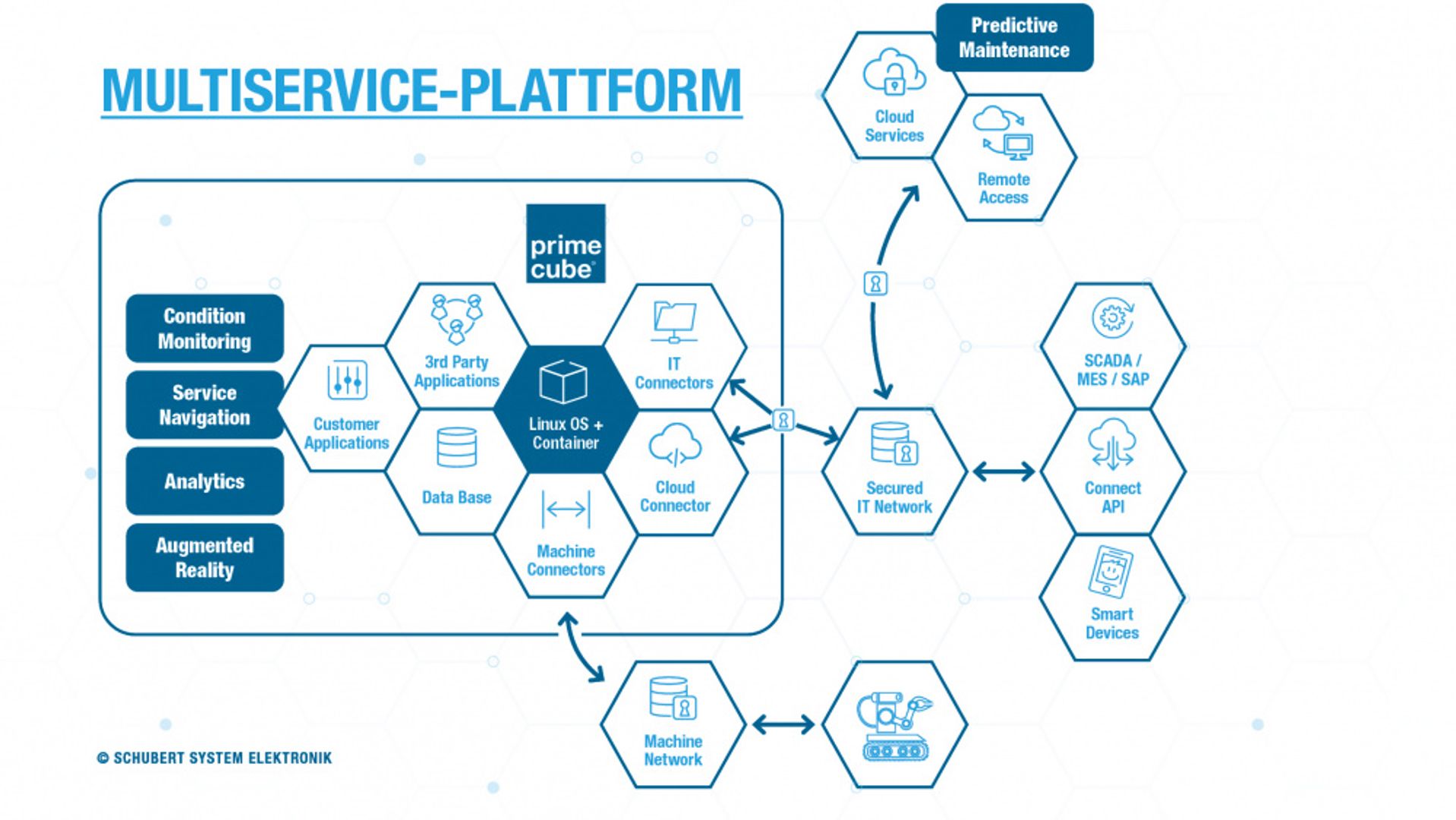

Multi-service platforms bundle services by means of container technology.

Intelligent data usage by edge computing should be realized as transparently and effectively as possible, with lean and customized systems. An MSP amalgamates several services into one system by means of container technology. The required data are recorded via interfaces, processed by defined applications and transferred to the cloud or another destination. Apart from data pre-processing and cloud interconnectedness, further tasks can be fulfilled in this way, e.g. virtual sensor systems or remote access to the installation.

The MSP can be realized on different hardware systems. Applications, connectors and third-party services are separated by means of containers (type 2 hypervisor). The container engine ensures the operation of different applications. The separation of the operating system from the application level and encrypted container communication enhance the security.

This creates a closed system that ensures the secure operation of all central services. The users can concentrate on their actual application expertise.

Virtual Sensor Systems: Planning for the Future with Learning Systems

The flexible micro-service architecture of the MSP allows the realization of virtual sensor concepts and therefore not only the deduction of important decision criteria for condition montoring but also for predictive maintenance.

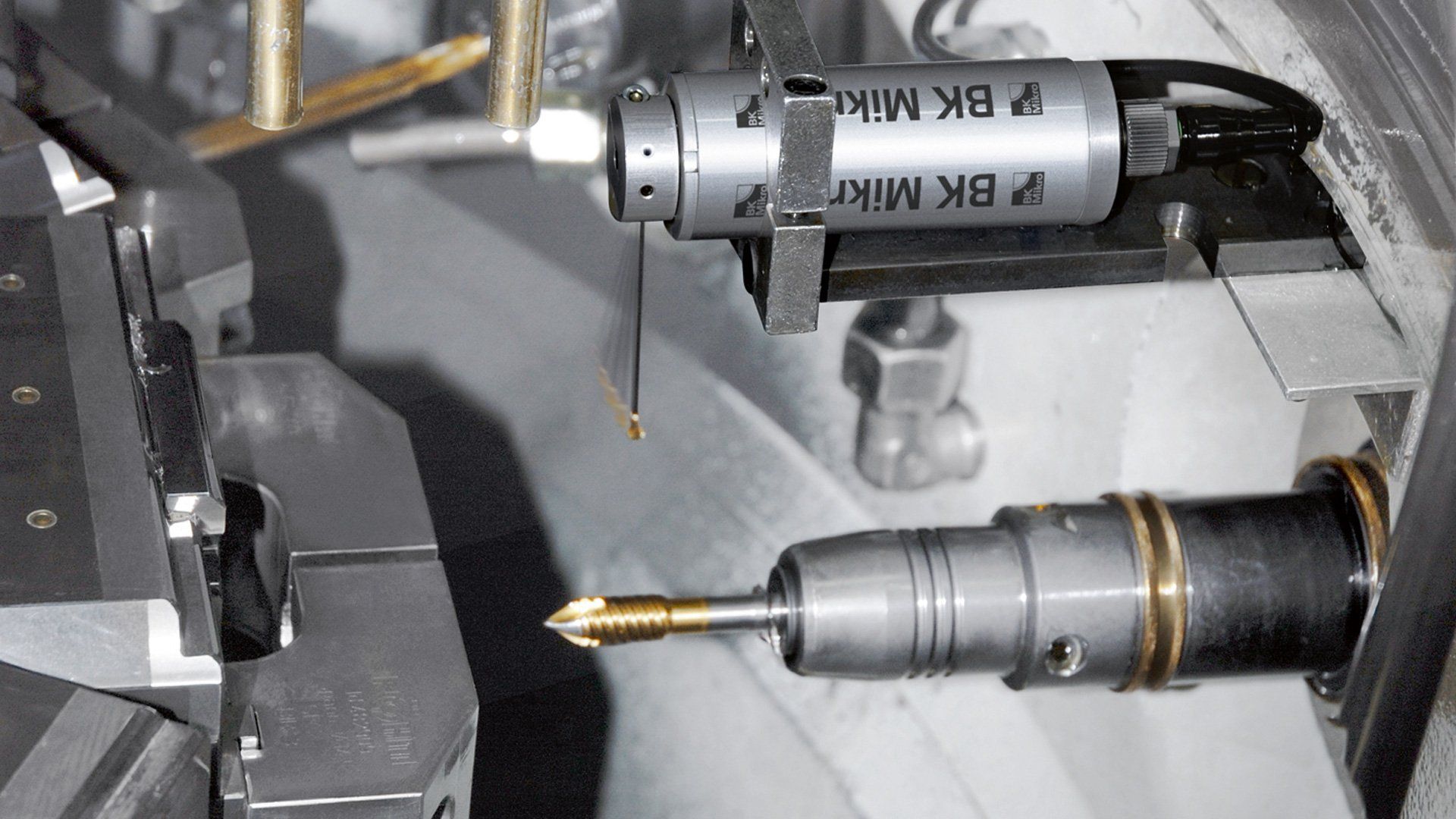

Real sensors can record a defined current condition but not make any superordinate statements on the quality level of the production process, as this requires to take into consideration different factors such as vibration, force and rotational speed.

A virtual sensor collects data that are detected by several real sensors. Within the MSP, they are linked from the OT-level to a sensor application via connectors. The correlation of the data allows to deduct summarizing insights that permit conclusions on the condition of processes, installations and machines. The transfer of these data into the cloud creates an information pool from which valuable knowledge about the behavior of the system and individual components can be deducted.

„Hardware Follows Software" – Professional System Advice for Optimum Data Usage.

The success of IIoT-solutions will increasingly depend on adequate software components that determine the selection of the hardware. Needs-based platforms combine both parts and enable the realization of individual requirements. Edge computing allows the optimum, economic and easy connection of sensors to the cloud. Due to the reduced data volume it can be performed with simple but robust technology.

Irrespective of all benefits, the challenges of IIoT also involve a high degree of complexity. Companies need to know and define their requirements very precisely to be able to use data in an optimum way, e.g. with respect to predictive maintenance.

Professional system consulting supports this process and ensures that the solution is perfectly customized to the respective requirements. The development experts from Schubert System Elektronik give advice to their customers from sensor systems to the control level and from the definition of powerful platforms in hardware and software and the selection of operating systems, virtualization and hypervisor solutions to the optimum connection to the cloud - under consideration of all relevant security aspects for the respective automation architecture.

Modular Computer Systems for Industry, Machine-building, Automation and More.

Prime Cube® stands for intelligent solutions in the areas of operating, visualizing, monitoring and controlling. Individual systems can be assembled from PC-based touch monitors for HMI-applications, performant box PCs, stable solutions for the transmission of video and USB data up to 100 m, extendable IIoT-concepts as well as software and service solutions.

Any Questions?

Maybe you now have concrete ideas how to optimize your own projects with respect to efficient data management by sensor-near edge solutions?

Our experts will be happy to support you during the complete development process and offer you professional system consulting.